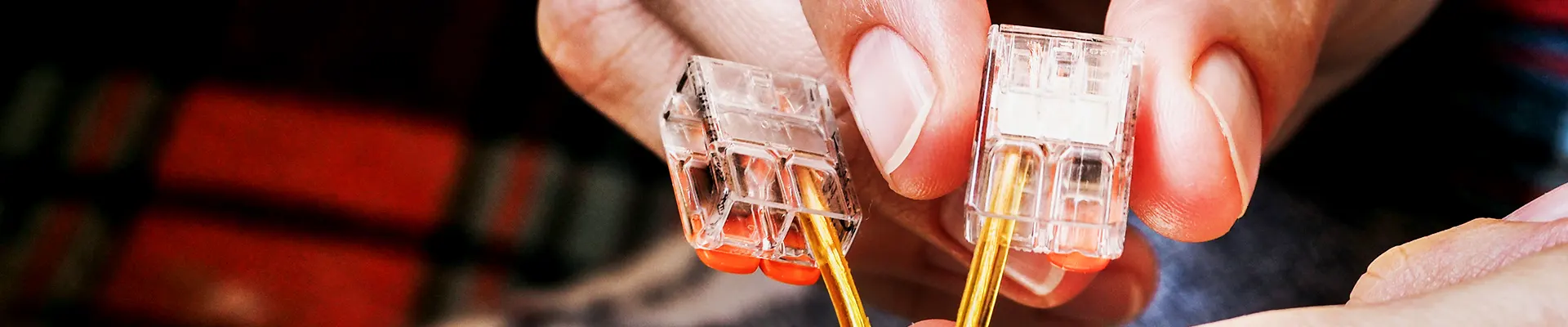

In recent years, the demand for high-quality Fast Wire Cable Connectors has surged, driven by advancements in technology and the increasing complexity of global electronic systems. According to a report by Mordor Intelligence, the global market for cable connectors is expected to reach approximately $70 billion by 2025, with a notable shift towards more efficient and reliable wiring solutions. As China continues to dominate manufacturing, it is vital for local producers to elevate their standards and embrace innovative techniques to satisfy this growing demand. This blog will delve into the detailed technical parameters of the best Fast Wire Cable Connectors available in the market today, along with a tutorial on selecting and utilizing these connectors effectively, ensuring they meet both international quality benchmarks and the specific needs of diverse applications.

In the rapidly evolving landscape of global manufacturing, the Chinese wire cable connector industry plays a pivotal role, particularly in the production of fast wire cable connectors. To meet escalating global demand, it is essential for manufacturers to elevate their quality standards. According to a recent report from the China Electronic Components Association, the international market for wire connectors is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2026. This growth presents both an opportunity and a challenge for manufacturers in China.

Implementing rigorous quality control measures is paramount. Manufacturers should invest in advanced testing technologies to ensure their products comply with international standards, such as ISO and UL certifications. A focus on supplier quality management is equally crucial; by establishing long-term partnerships with reliable suppliers, manufacturers can enhance the consistency and dependability of their components.

**Tip:** Consider adopting lean manufacturing techniques to minimize waste and optimize production processes. Another effective strategy is to implement continuous training programs for employees, fostering a culture of quality and efficiency. By elevating manufacturing standards, Chinese manufacturers can position themselves favorably in the global marketplace and meet the demands of consumers for high-quality wire cable connectors.

In the rapidly evolving landscape of manufacturing, the integration of automation and Industry 4.0 technologies plays a pivotal role in the production of fast wire cable connectors. Automation not only enhances efficiency but also ensures precision in manufacturing processes. Advanced robotics and automated assembly lines streamline operations, reducing production times and minimizing human error. By leveraging these technologies, Chinese manufacturers are elevating the quality of their products, making them more competitive in the global market.

Moreover, Industry 4.0 introduces a paradigm shift with the incorporation of smart technologies such as the Internet of Things (IoT) and big data analytics. These innovations enable manufacturers to monitor production in real-time, leading to immediate adjustments and improvements in quality control. Predictive maintenance, powered by data analytics, ensures that machinery operates at peak efficiency, further enhancing product reliability. As Chinese manufacturers embrace this digital transformation, they are poised to meet global demands with superior wire cable connectors that reflect both innovation and durability.

Chinese manufacturers face significant challenges in meeting global quality standards, particularly in the production of fast wire cable connectors. As the demand for high-quality components rises internationally, manufacturers must navigate complex regulations, variations in quality benchmarks, and the need for consistent production practices. This requires a thorough understanding of both domestic and international standards, which are often subject to change and can vary widely.

In response to these challenges, many Chinese manufacturers are investing in advanced technologies and quality management systems. Implementing rigorous testing protocols and certifications not only enhances product reliability but also builds credibility with global customers. Moreover, fostering a culture of continuous improvement and training among employees ensures that manufacturers can adapt to evolving quality demands. By prioritizing these strategies, Chinese manufacturers can elevate their production quality, positioning themselves favorably in the global market.

The future of cable connectors is being shaped by innovative materials and technologies that enhance both performance and reliability. In the competitive landscape of fast wire cable connectors, manufacturers in China are embracing advanced composites and high-conductivity metals to produce connectors that not only meet global industry standards but also exceed customer expectations. These materials exhibit superior resistance to environmental factors such as temperature fluctuations and moisture, ensuring longevity and durability in various applications.

Furthermore, technological advancements in manufacturing processes, such as automated precision assembly and 3D printing, are enabling the production of intricate designs that were previously impossible. These innovations not only streamline production but also allow for customization tailored to specific market needs. As a result, Chinese manufacturers are positioned to deliver high-quality connectors that fulfill the growing demand across sectors, from telecommunications to renewable energy, establishing a strong foothold in the global marketplace.

| Connector Type | Material Used | Max Current (A) | Temperature Range (°C) | Standards Compliance |

|---|---|---|---|---|

| Fast Connector A | Copper Alloy | 30 | -40 to 105 | ISO 9001 |

| Fast Connector B | Aluminum | 50 | -40 to 85 | UL Listed |

| Fast Connector C | Nickel Plated Steel | 40 | -30 to 90 | IEC 61210 |

| Fast Connector D | High-Density Polymer | 25 | -20 to 75 | RoHS Compliant |

| Fast Connector E | Conductive Plastic | 35 | -40 to 100 | CE Certified |

Sustainability is becoming an essential aspect of manufacturing, particularly in the production of fast wire cable connectors. As the global demand for electric vehicles (EVs) and advanced telecommunications infrastructure grows, the need for sustainable practices in this sector intensifies. Chinese manufacturers are stepping up their commitment to eco-friendly processes by exploring recyclable and biodegradable materials for cable production. This shift not only reduces environmental impact but also aligns with the increasing consumer preference for sustainably sourced products.

The proliferation of 5G networks and the rise of electric vehicle charging infrastructure present unique challenges and opportunities for the fast wire cable connector market. As these industries expand, the integration of sustainable materials can enhance both performance and environmental responsibility. For instance, developing connectors from biodegradable materials not only contributes to reducing electronic waste but also positions manufacturers favorably in a competitive market where eco-consciousness is paramount. Embracing sustainability in manufacturing not only meets regulatory requirements but also reflects a commitment to the planet and future generations.