When it comes to successfully executing electrical projects, selecting the right components is crucial, and this is where the WAGO 773 Series Quickly Wire Connector shines as an exceptional choice. This versatile connector is designed to simplify wiring processes while ensuring secure and reliable connections. However, with numerous options available in the market, finding a quality supplier can be daunting.

In this ultimate guide, we will provide you with five essential tips to quickly identify the best WAGO 773 Series Quickly Wire Connector for your projects. By focusing on supplier credibility, product specifications, customer service, and more, you’ll be equipped with the knowledge to make informed decisions and optimize your project outcomes. Whether you're a seasoned professional or a DIY enthusiast, understanding how to choose the right connector can greatly enhance your efficiency and effectiveness in wiring applications.

When selecting the best WAGO 773 Series wire connectors for your projects, it's crucial to consider key features that ensure optimal performance and reliability. Among these, the conductor cross-section range is essential, as it determines the compatibility with various wire gauges. The WAGO 773 Series connectors accommodate multiple wire sizes, providing flexibility for different applications. According to industry reports, connectors that support a wider range of conductor sizes can significantly reduce installation time and improve overall project efficiency.

Another vital aspect is the connector's rated voltage and current capabilities. The WAGO 773 connectors are designed to handle high electrical loads, making them suitable for a variety of demanding applications in industrial and commercial settings. Reports have shown that high-quality connectors can withstand increased heat and reduce the risk of failure, thus enhancing safety and performance longevity. Additionally, the insulation material used in these connectors contributes to their durability, protecting connections from environmental factors and ensuring reliable operation over time.

Another vital aspect is the connector's rated voltage and current capabilities. The WAGO 773 connectors are designed to handle high electrical loads, making them suitable for a variety of demanding applications in industrial and commercial settings. Reports have shown that high-quality connectors can withstand increased heat and reduce the risk of failure, thus enhancing safety and performance longevity. Additionally, the insulation material used in these connectors contributes to their durability, protecting connections from environmental factors and ensuring reliable operation over time.

In today's market, emerging products like insulation displacement connectors and quick splice terminals are gaining attention for their ease of use and efficiency. These innovations highlight the ongoing advancements in wire connection technologies, allowing users to achieve dependable and swift installations. When choosing wire connectors, staying informed about the latest developments and specifications is essential for making the best choice for your project's needs.

When embarking on a new electrical project, understanding your specific wiring requirements is crucial to ensure safety and efficiency. According to the National Electric Code (NEC), approximately 60% of electrical failures can be traced back to improper or insufficient wiring practices. This statistic underscores the importance of selecting the right components, such as WAGO 773 Series Quick Wire Connectors, which are designed to meet both industry standards and the specific demands of various applications.

Wiring requirements can vary significantly based on project types, be it residential, commercial, or industrial. For instance, a report by the International Electrotechnical Commission highlights that projects involving high-power applications necessitate connectors that can handle greater current loads and thermal management. The WAGO 773 Series offers a range of connector sizes and configurations, ensuring that you can find the perfect match for your particular needs. Moreover, the ease of installation provided by these quick connectors can save time and reduce labor costs, making them an ideal choice for both novice and professional electricians.

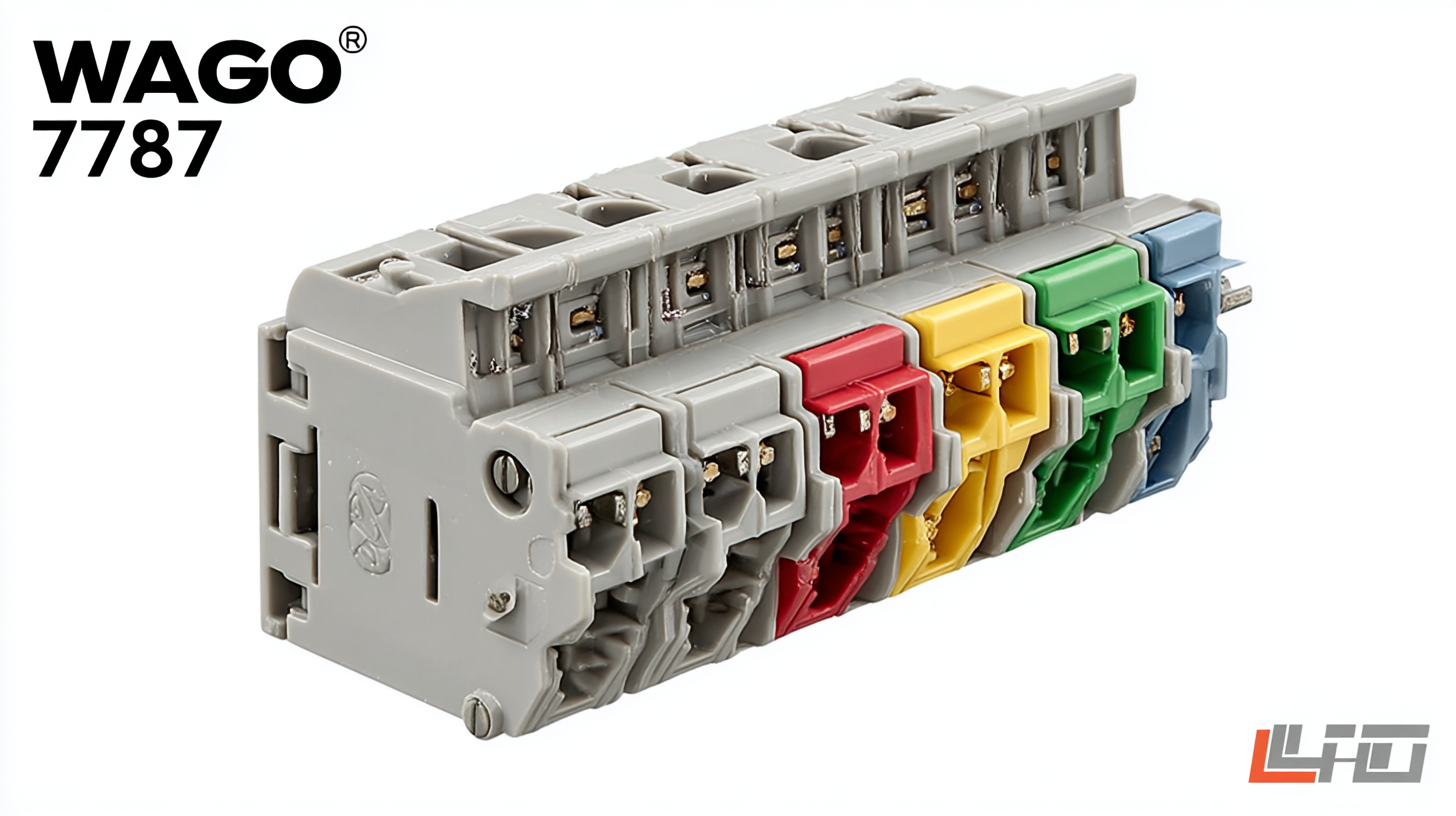

When selecting the best connector from the WAGO 773 series for your projects, it's essential to compare the various models available. WAGO offers a range of options that cater to different wiring needs, from simple applications to complex configurations. Each model within the 773 series features its unique specifications, such as the number of terminals, wire size capabilities, and different actuation mechanisms that suit specific installation environments.

For instance, the WAGO 773-100 model is ideal for compact spaces and allows for easy insertion of wires, making it a perfect choice for residential applications. Meanwhile, the 773-200 model offers greater flexibility with its push-in technology, accommodating a wider range of wire types and sizes, which can be particularly advantageous for industrial settings where customization is required. By analyzing these distinctions, you can quickly identify which model aligns best with your project's demands, ensuring optimal performance and reliability in your electrical connections.

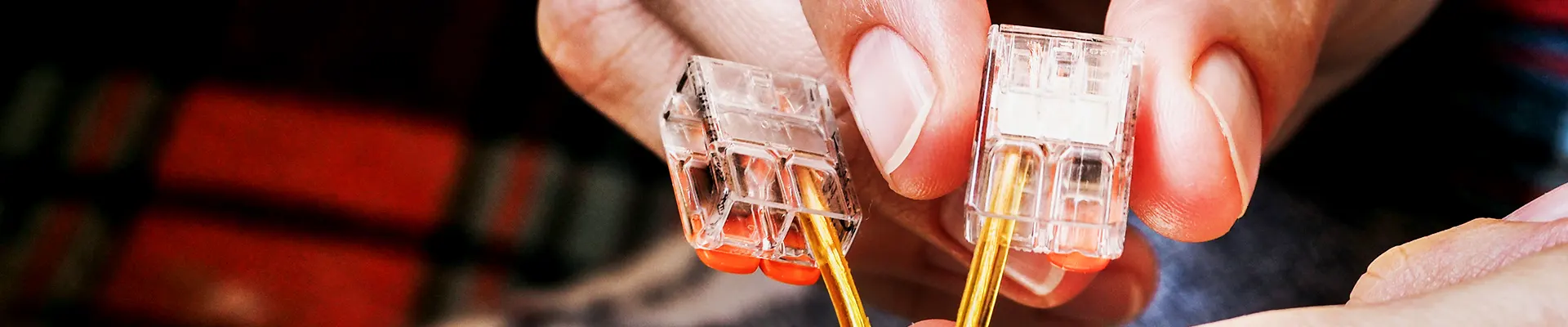

When it comes to installing wire connectors, the WAGO 773 Series stands out for its reliability and versatility. Best practices for utilizing these connectors ensure a secure and efficient electrical connection. First, it is essential to select the proper connector type based on the application requirements, including the number of wires and the environmental conditions they will face.

The connectors are designed for easy handling, allowing for quick and secure installation while ensuring minimal strain on the wires.

Moreover, maintaining a clean installation area is crucial for optimal performance. Ensure that the wires are stripped to the recommended length and free from any debris or damages. As a recent extension of the connector family has introduced additional components for improved mounting and strain relief, make sure to leverage these features during installation.

By adhering to these best practices, you can maximize the efficiency and longevity of your WAGO connections, ensuring safety and reliability in your projects.

Choosing wire connectors, particularly the WAGO 773 Series, can be a straightforward process if you steer clear of common mistakes. One frequent error is overlooking the wire gauge compatibility. Each connector supports specific wire sizes, and using an incompatible gauge can lead to poor connections, resulting in performance issues or even system failures. Always check the specifications to ensure the connector matches your project needs.

Another pitfall to avoid is failing to consider the application environment. Different connectors are designed for various settings, whether it’s a dry indoor space or a wet outdoor environment. Choosing a connector that isn’t rated for your specific conditions can compromise safety and reliability. For example, connectors intended for outdoor use often come with enhanced weatherproofing features, which are essential in preventing corrosion and electrical failures. By paying close attention to these factors, you can select the best WAGO 773 Series connector that meets your project’s requirements.

| Tip Number | Tip Description | Common Mistake | Consequence |

|---|---|---|---|

| 1 | Identify the wire gauge required for your project. | Choosing the wrong wire gauge. | Overheating and potential fire hazards. |

| 2 | Check the voltage and current ratings of connectors. | Ignoring voltage ratings. | Risk of electrical failure. |

| 3 | Consider the environmental conditions. | Not accounting for moisture or dust. | Corrosion and connectivity issues. |

| 4 | Ensure compatibility with existing hardware. | Choosing connectors that don't fit. | Incompatibility leading to project delays. |

| 5 | Look for certifications and standards compliance. | Overlooking certification requirements. | Legal and safety liabilities. |